COOKIE OVERVIEW

This website uses cookies so we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful. You can adjust your preferences below.

More information about our Cookie Policy.

ESSENTIAL COOKIES

Essential Cookies are enabled at all times so that we can save your preferences for cookie settings. These cookies do not collect any personal or sensitive information or IP addresses. Furthermore, the information they store is not sent to any 3rd parties.

TRACKING COOKIES

This website uses third party cookies such as Google Analytics to collect anonymous information, for example the number of visitors to the site, and the most popular pages. Keeping this cookie enabled helps us to improve our website.

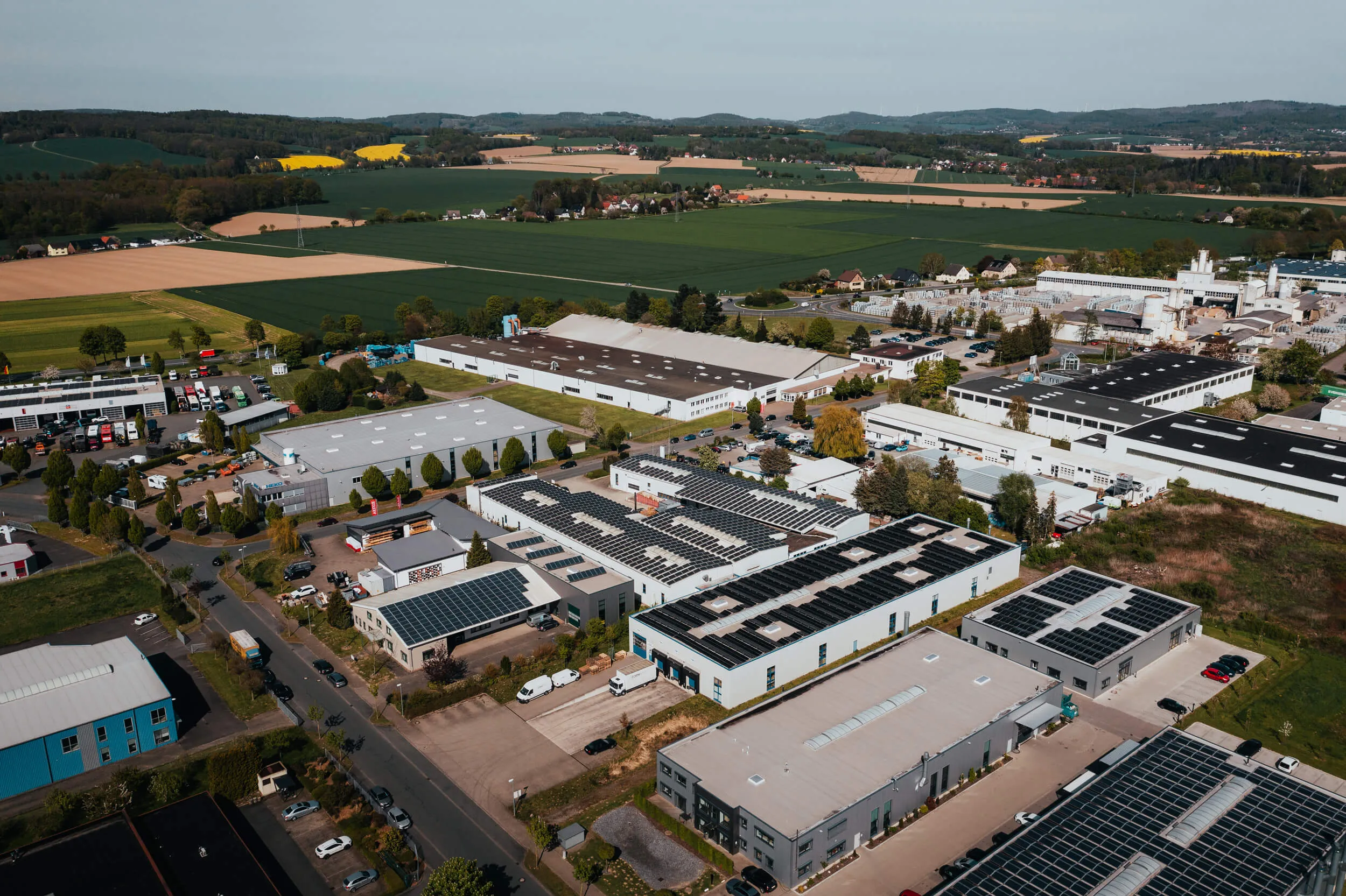

Formatio is entirely self-sufficient in its energy needs, using no external commercial energy suppliers.

Our large photovoltaic system, mounted on the factory roof, generates 300,000 KWh of energy, of which we consume about 150,000 KWh annually. The surplus electricity is fed into the public grid.

Wooden offcuts which have no further utility production of new products and are designated ‘end of life’ are burnt using our high efficiency wood burner to generate heat during the cooler months. This has the added benefit of lowering the CO2 emissions associated with third party collection and disposal of this waste.

We have been proactive in the provision of Electric charging points for our employee vehicles and incentivise their use.

We source wood exclusively from verified and certified suppliers, ensuring its sustainability as a renewable raw material. True sustainability requires comprehensive forest management aligned with economic, ecological, and social criteria. To validate this commitment, our supply chains undergo rigorous scrutiny.

All our wood-based products undergo verification by independent third parties, adhering to ISO 38200 or equivalent standards, guaranteeing the legality of the wood’s origin. Moreover, our wood sources hold certifications under FSC and PEFC standards, ensuring a traceable chain of custody.

We choose engineered boards from suppliers which offer the highest content of recycled wood material. These boards not only adhere to our stringent standards for strength and finish quality but also contribute to a reduced environmental footprint.

By selecting boards with high recycled wood content, we play our part to reintroduce materials that have already been utilized, promoting a circular economy. Our approach to sourcing engineered wood boards prioritizes recycled wood content in the first instance, while using only sustainable forestry wood as the remaining component. This strategy aims to prolong the wood’s lifecycle and minimize the consumption of newly harvested wood.

As a specialist in manufacturing wooden products, we use our purchasing power to ensure the most sustainable outcomes in the circular ‘wood’ economy.